Please allow 16 weeks for creation.

Cut by Time: A History of Gemstone Shapes, Technology, and Jewelry Trends

|

|

Time to read 23 min

My Cart

Your Cart Is Empty

Continue shopping|

|

Time to read 23 min

Throughout human history, the shaping of gemstones has served as both an aesthetic endeavor and a technological triumph. The earliest lapidaries worked by firelight and instinct, turning raw crystal into meaning with copper tools and powdered stone. Later centuries brought symmetry, machinery, and mathematics. But always, the question remained: what should brilliance look like?

From the bow drills of Mesopotamia to the diamond-scored lattices of the digital age, we trace not only the evolution of gemstone cuts, but how trends were born, refined, and sometimes even resurrected. Along the way, we’ll dive into the stories behind popular cuts, the innovations that made them possible, and the cultural meanings layered into each glittering angle.

Long before diamonds were faceted into brilliance, gemstones were shaped by hand, by heat, and by reverence. In ancient Egypt, Mesopotamia, and the Indus Valley, early lapidaries practiced a kind of sacred alchemy.

The most common cut of this era wasn’t a cut at all by today’s standards, it was the cabochon. Smooth, domed, and unfaceted, cabochons emphasized color over clarity, and surface over sparkle. Deep blue lapis lazuli, blood-red carnelian, and sky-pale turquoise were shaped into amulets, seals, and inlays, not to catch the light, but to hold meaning. Each one carried cultural and spiritual weight: lapis as the stone of the gods, carnelian as a symbol of life-force, and turquoise as protection against evil.

The tools used were simple but effective. Artisans employed bow drills tipped with copper, using quartz sand as an abrasive to steadily wear away stone surfaces. In ancient Egypt, flywheel drills enabled craftsmen to create precise hollows for intricate beadwork and ornaments, achieving remarkable smoothness through patient repetition.

In Mesopotamia, cylinder seals carved from gemstones became sophisticated personal identifiers, and they were pressed into clay to produce geometric patterns. Rather than serving merely as decoration, these seals functioned as wearable tokens of identity and power, embedding a culture’s symbols into enduring physical forms.

Ever wondered how artisans in 1500 BCE managed to inscribe such delicate detail onto something as small as a scarab? The process, equal parts science and devotion, reveals just how advanced these early lapidaries were. Here’s how it was done:

Many scarabs weren’t carved from gemstone at all. Most were made of Egyptian faience—a non-clay ceramic crafted from crushed quartz or sand, then coated in a blue-green copper glaze and fired at low temperatures. Others were shaped from steatite (soapstone), which was soft enough to carve when raw but hardened into a durable surface after firing.

Copper, though too soft to cut stone on its own, was sharpened into gravers and paired with abrasives—finely ground quartz sand, or crushed garnet. These materials did the real cutting, wearing away at the stone’s surface grain by grain. For fine detail, artisans also used flint blades, their edges chiseled down to surgical sharpness.

Carvers didn’t strike, they scraped. Using a methodical push-and-draw motion, guided by the hands and sometimes braced against leather pads or clamps, they incised the tiniest hieroglyphs and reliefs. Sunlight or polished copper mirrors helped illuminate the work. The goal wasn’t speed, it was precision. Depth and relief were achieved through countless patient strokes.

Once the carving was complete, the final steps depended on the material.

If it was faience then the scarab was coated in a copper-based glaze and fired, yielding the iconic turquoise glow. And if stone, it was then polished with leather and powdered abrasives, revealing its natural luster and refining the lines to tactile smoothness.

Though some consider it crude by modern standards, these early innovations laid the groundwork for everything to come. They remind us that in jewelry, technique has always been inseparable from belief. A cut is never just a cut, it’s a worldview, shaped by the hands and tools of its time.

While much of the ancient world polished stones for color and symbolism, it was India—the world’s first known source of diamonds—that laid the early foundations for deliberate gem shaping. As early as the 4th century BCE, Indian lapidaries were refining diamonds not to enhance brilliance, but to reveal geometry.

Unlike Western traditions that would later favor sparkle and cut, Indian lapidaries believed in preserving the diamond’s natural integrity. Faceting was avoided. Instead, craftsmen used manual cleaving, often by pressing one diamond against another, to expose clean faces, and reveal the stone’s inner purity.

These diamonds were often octahedral or rhomboid in shape, allowing for symmetry with minimal loss. And that made them revolutionary. This method marked one of the first steps toward shaping gemstones for control, turning a raw mineral into an object with engineered form.

Though the famed Golconda mines wouldn’t be discovered until the 17th century, the techniques that would later make that region famous were already in use in other parts of the subcontinent. This early restraint shaped the way diamonds would be understood for centuries.

Meanwhile, across the Mediterranean, Greek and Roman lapidaries developed carving techniques distinct from their Egyptian predecessors, marked by significant innovations in precision engraving, tooling, and design complexity. Rather than simply drilling or smoothing surfaces, Greco-Roman artisans specialized in the intricate carving of intaglios—designs recessed into stones, intended for stamping wax or clay—and cameos, featuring raised figures emerging vividly from layered gemstones.

The major technological advancement that set Greco-Roman methods apart was their sophisticated use of emery powder, an abrasive mineral sourced from the Greek island of Naxos, was far harder and finer than the quartz-based abrasives used by Egyptians. This emery allowed lapidaries to achieve a previously unmatched level of detail, capable of precise, shallow engravings that revealed subtle nuances of expression, anatomy, and symbolism.

Specifically, they employed specialized metal engraving tools known as burins, made of hardened iron or bronze alloys, designed to work in conjunction with the abrasive emery powder. These burins were pushed by hand, enabling carvers to execute fine linear details and delicate shading impossible with simple rotational drills alone. This technique, known as “wheel-cutting” or “manual engraving,” involved carefully scraping and pressing into the stone, layer by layer, producing meticulous outlines and sophisticated, miniature reliefs.

Greco-Roman lapidaries mastered the control of depth perception through nuanced carving, achieving intricate bas-reliefs in cameos by exploiting the natural bands of layered agate or sardonyx. They recognized the optical and aesthetic possibilities inherent in a stone’s stratified colors and textures, strategically carving through contrasting layers to vividly define foreground from background.

Unlike Egyptian methods, which typically focused on uniform, polished surfaces and hollow drills, Greco-Roman artisans deliberately created narrative complexity within their gemstones. Their carved scenes captured dynamic mythological or historical events, detailed portraits, and symbolic iconography, each executed with precise anatomical accuracy and nuanced visual storytelling.

These carved gemstones were highly functional as intricate signets, personal identifiers, and status indicators, becoming artifacts that communicated explicit messages about identity, authority, and cultural memory through the precise language of carving itself.

Europe’s Flat Period

After the classical ingenuity of the Greco-Roman world, much of medieval Europe entered a phase of lapidary stagnation. From roughly 500 to 1000 CE, the art of gem cutting retreated into silence. Stones were valued, yes, but not shaped. Faceting vanished, and with it, the desire to manipulate light.

What remained was polishing. Gemstones were ground smooth and domed, but rarely sculpted beyond their natural form. Even intaglio and cameo traditions faded. Stones were selected for their color, size, and religious symbolism, not their brilliance or symmetry.

This period saw the rise of jewels as reliquaries, sacred objects embedded in chalices, crucifixes, and shrines. Gems were believed to carry divine power through their untouched essence and biblical resonance. A sapphire might represent heaven, a garnet, the blood of Christ. These weren’t adornments, they were theological instruments, fastened to wood and gold like pieces of the Passion.

Stonework, in this sense, was subservient to metalwork. The lapidary arts became functionally dormant, tucked into ecclesiastical hands. Gem cutting as an art, at least in Europe, had entered a long winter.

Even as cutting techniques lay dormant, medieval scholars maintained and transmitted ancient gem knowledge, often through poetic treatises.

Marbode of Rennes (d. 1123) authored the famously terse yet rich Liber de Lapidibus, which was a hexametric verse cataloging 60 stones, their origins, medicinal properties, and metaphysical virtues. This work was widely circulated across Europe and translated into French, Italian, Hebrew, Provençal, and English—and helped preserve Roman and Arabic lapidary traditions through the so-called “medieval scientific revival”.

These texts were practical references, used by clergy, artisans, and physicians who relied on the stones’ perceived powers, from healing to spiritual protection.

If you would like to take a musing at the English translation here is the link.

While medieval Europe lapsed into lapidary dormancy, lapidaries in the Abbasid Caliphate (750–1258 CE) pioneered transformative techniques that set them distinctly apart from earlier practices. Abbasid craftsmen innovated not only in tooling but also in their foundational understanding of materials, greatly expanding the capabilities of gemstone working.

Foremost among these advancements was their systematic refinement of abrasive technology. Unlike the quartz sands used previously, Abbasid lapidaries harnessed the unparalleled hardness of corundum minerals (miner’s grit)—specifically crushed rubies and sapphires—to create abrasives significantly more effective at cutting and engraving harder gemstones.

These corundum abrasives, graded meticulously by particle size, allowed for exceptional control and precision previously unattainable. Artisans applied this abrasive slurry to small iron or soft-steel styluses, then carving details and geometric patterns into gemstones such as quartz and emerald, and even achieving occasional faceting of diamonds, a feat not documented in earlier traditions.

This method enabled the creation of intricate arabesques and symmetrical interlacings characteristic of Islamic decorative arts, extending gemstone carving beyond narrative depiction into elaborate geometric abstraction.

The Abbasid elevation in technique extended seamlessly to their mastery of stone-metal inlay. Here artisans shined in planning geometric forms and symmetries to embed the polished gems into complex tessellations and elaborate ornamental mosaics. This practice later allowed gemstones to become integral elements in scientific instruments such as astrolabes, luxury objects including chalices and brooches, as well as architectural adornments, laying essential foundations for later zellij tilework and intricate muqarnas ceilings.

This precise combination of refined abrasives, controlled manual engraving, and complex inlay craftsmanship represented a fundamental reimagining of the gemstone’s artistic potential. Abbasid lapidaries thus distinguished themselves by developing methods that later influenced medieval techniques in both the Islamic world and Europe.

As Europe stirred from its medieval slumber, the world of gemstones awakened with it. No longer content with cabochons or sacred polish, lapidaries in Bruges and Antwerp ushered in a revolution that would alter gem cutting forever. Their ambition was no longer piety, it was light.

By the late 14th century, cutters in Bruges began experimenting with a technique known as the table cut: cleaving a diamond to create a flat top and four surrounding facets. In this time, it was often created by cutting one of the points off a octahedral diamond, leaving the ‘table’. Primitive by modern measures, yes, but it marked a seismic shift. For the first time in Western history, diamonds were not merely worn, they were engineered.

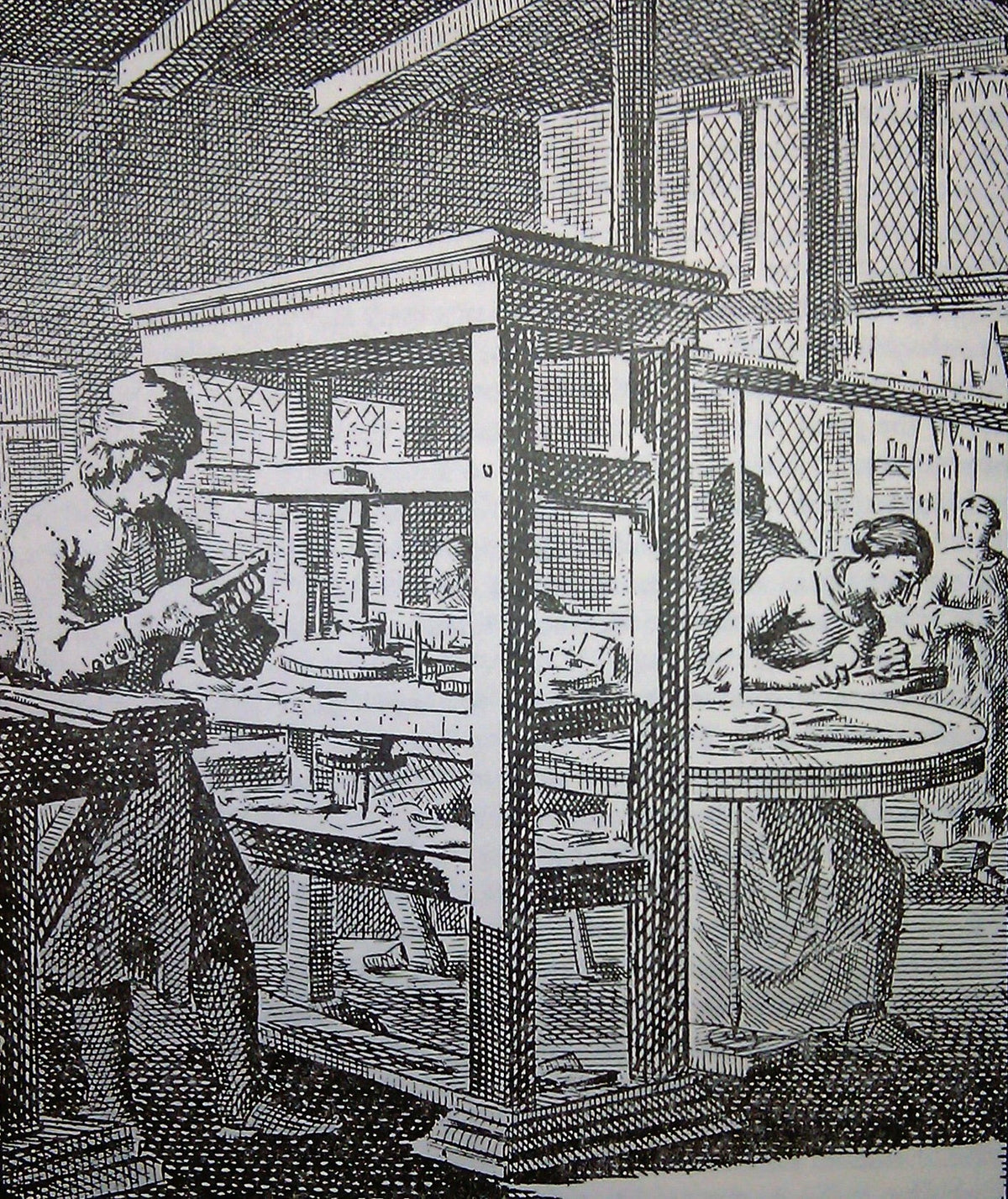

Yet the scaif (the device credited with transforming this ambition into precision) bears a more complex origin than once believed.

Lodewyk van Berquem of Bruges is often lauded for its invention in 1456, however recent scholarship reveals that mechanized faceting wheels—including horizontal polishing discs—appear in illustrated manuscripts as early as the 1430s, notably in the Codex Latinus Monacensis and the treatises of Henri Arnaut de Zwolle.

These early tools, suggest that Berquem did not create the idea ex nihilo, but rather refined and popularized it with unmatched finesse. His version of the scaif, infused with diamond dust and olive oil, allowed for the polishing of symmetrical facets with clarity and control.

Under van Bercken’s hands, the dormant point cut, preserving the diamond’s natural octahedral form, was revived alongside the refined table cut, and he is credited with conceiving the earliest briolette, marking the first intentional pear shape.

But his legacy was more than technique, it was philosophy. Many historians argue he saw symmetry as a moral and spiritual ideal, in line with late medieval sacred geometry. The scaif was thus a means to perfect nature via reason.

This intellectual elegance attracted the Burgundian court, especially in Bruges and Antwerp, centers of wealth and art. The demand for consistent brilliance and symmetric beauty wasn’t frivolous, it was political.

Diamond rings became tokens of fidelity and power by the 15th century, emblematic of clarity, virtue, and sovereignty in ducal marriages. Yet where brilliance flourished, fraud soon followed, prompting the earliest efforts toward standardized gem certification and workshop regulation—the first stirrings of a luxury trade under scrutiny.

Originating in the late 16th-century Netherlands, the Rose Cut diamond became emblematic of the early Baroque era. It was designed for shallow diamond crystals, using a flat base and a domed crown of 3 to 24 triangular facets resembling the unfolding petals of a rosebud. This cut was specifically designed to maximize sparkle under candlelit settings common in European courts.

This era saw key technological advances in the scaif, the Baroque version evolved to include multiple interchangeable laps made from lead, tin, and copper, each with different abrasives. These adaptations allowed cutters to refine not just diamonds but a wider range of stones.

In 17th-century France, the Mazarin Cut emerged under the patronage of Cardinal Jules Mazarin, the influential advisor to King Louis XIV and a renowned collector of gems. Featuring 17 symmetrical facets on the crown, typically in oval or rounded-square shapes, the Mazarin Cut represented a significant evolution toward symmetry.

By the late 1700s, the Old Mine Cut became a new hallmark of diamond cutting innovation. It has a distinctive cushion-shaped outline, high crown, small table facet, and pronounced culet (the small facet at the bottom tip of the stone). The Old Mine Cut flourished due to increased diamond supplies from Brazil, Minas Gerais region, which produced larger and more irregular stones than the famed Golconda mines of India.

In 17th-century France, the Mazarin Cut emerged under the patronage of Cardinal Jules Mazarin, the influential advisor to King Louis XIV and a renowned collector of gems. Featuring 17 symmetrical facets on the crown, typically in oval or rounded-square shapes, the Mazarin Cut represented a significant evolution toward symmetry.

To accommodate this new material, lapidaries developed tools and techniques that allowed for more precise and consistent faceting such as:

Foot-powered treadle wheels, which replaced hand-rotated wheels and allowed for more consistent polishing pressure.

Metallic polishing laps, often made of cast iron, enabling stronger friction and finer control.

Early gear systems and indexing arms, precursors to modern faceting machines, which helped achieve greater regularity in facet angles.

These advancements were complemented by the development of hardened steel tools and improved abrasives, including garnet dust. Together, they expanded the lapidary repertoire to include a wider range of gemstones beyond diamonds.

In 17th-century France, under the reign of Louis XIV, the crown heavily invested in diamond acquisition and gem-cutting innovation. Jean-Baptiste Tavernier (1605–1689), a French gem merchant and traveler, made six documented voyages to India and Persia. His procurement of the 115-carat Tavernier Blue diamond from the Kollur Mine in Golconda, India, marked a pivotal moment in gem history.

This diamond was later re-cut into the 69-carat French Blue and eventually became the Hope Diamond. Tavernier’s published accounts, including “Les Six Voyages de J.B. Tavernier,” significantly influenced European gem trading routes and introduced Indian cutting and valuation systems to Western markets.

Meanwhile, in England, gem-cutting and jewelry design were equally influenced by Enlightenment-era science. Isaac Newton’s 1704 treatise “Opticks” spurred interest in the dispersion and reflection of light. English settings from this period favored closed-back mounts lined with metallic foil to enhance brilliance under candlelight.

The hammer of the Industrial Revolution reshaped gemcraft. Steam-powered lathes and saws—descendants of early machine tools developed by British engineer Henry Maudslay—ushered in a new era of mechanical precision.

Maudslay’s early 19th-century slide-rest lathe, was designed for cutting uniform metal threads and introduced the industrial principle of repeatable accuracy. Though not intended for gemstones, it laid the mechanical foundation for the powered faceting wheels that followed.

By the 1860s, steam-powered polishing rigs were in use across Europe. In the United States, Henry D. Morse, often considered the father of American diamond cutting, opened a Boston factory that radically modernized lapidary work. His shop, later relocated to New York, operated 24 then 52 steam-driven wheels, rotating at up to 1,500 rpm. Morse developed custom gauges to control facet angles, shifting the craft toward mathematical precision rather than intuitive shaping. His colleague, Charles M. Field, co-patented one of the earliest American bruting machines in 1874, bringing fully mechanized rounding to domestic production.

The advantage was clear, cuts that once took days now concluded in hours, with dramatically reduced labor and greater uniformity.

Steam-driven saws of the era introduced metallurgically hardened blades, using carbide grit and oil lubrication to slice through raw crystal. This represented a vivid contrast to earlier methods, which relied on hand-held copper frames and abrasive dust. The new approach produced cleaner, straighter facets and significantly less mechanical damage to the stone.

Bruting machines, first adopted in the 1860s, also marked a key shift. Two diamond-encrusted wheels were rotated against one another to “round” a rough gem into a symmetrical girdle. Before this, cutters relied on hand-held lapidary wheels or brute friction—a slow and imprecise process that often led to irregular outlines. Mechanized bruting made the circular form replicable at scale.

If you would like to see Morse's entire journal visit here.

Old European Cut: the era’s crowning achievement. More round and symmetrical than earlier hand-cut stones, but with large culets and chunky crowns, it fused fire with vintage elegance, a clear forebear to today’s brilliant round.

Rose Cut: flat-bottomed with a domed pavilion of triangular facets, favored for its candlelit sparkle.

Cushion Cut: soft-shouldered squares with truncated corners, its pillowy form suited the romantic aesthetic of mid-century jewelry.

Heart-Shaped gems: flourishing mid-1800s, they embodied sentimental symbolism, gifts of devotion or melancholic love tokens.

Mourning Jewelry : diamonds and blackened gemstones—jet (fossilized wood), banded agate—were incorporated into brooches, rings, and lockets designed to memorialize the deceased, especially in the wake of Prince Albert’s death in 1861. These symbolic gems were worn close to the heart, sometimes with woven hair of the departed, a convergence of geology, grief, and societal rituals.

In 1867, the discovery of a 21.19-carat rough diamond on a farm near the Orange River in South Africa marked a seismic shift in the global gemstone trade. Found by a young boy named Erasmus Jacobs, the stone sparked intense public interest.

By 1870, diamond-bearing gravels along the Vaal and Orange Rivers had transformed the landscape: alluvial diggings near Kimberley and Barkly West drew thousands of hopeful prospectors, creating sprawling, chaotic mining camps. These early operations were rudimentary—workers used hammered metal sieves and, later, finer 1.6 mm mesh screens—to separate stones from gravel. Though effective, these techniques required immense physical labor and relied on an exploitative labor structure that soon became formalized under colonial rule.

Meanwhile, Antwerp, Belgium, emerged as Europe’s dominant diamond cutting center. While Amsterdam had long held that title, Antwerp’s embrace of mechanization—and its social infrastructure—enabled it to overtake its rival by the end of the 19th century. The city expanded rapidly: by the early 1900s, it hosted more than 380 diamond workshops and over 1,500 firms, with more than half of the world’s polished stones passing through its channels. Antwerp’s cutting houses adopted the steam-powered bruting lines (previously mentioned) and polishing machines, increasing both the speed and accuracy of gemstone processing.

This industrial evolution was supported by a growing labor movement, including the founding of the Antwerp Diamond Workers’ Union in 1895, which helped structure and protect the workforce. At the same time, the city formalized its dominance through institutional bodies like the Antwerp World Diamond Centre and a network of diamond exchanges, establishing global benchmarks for quality, trade, and price. Antwerp wasn’t just cutting stones; it was standardizing how the world measured them.

The Art Nouveau movement, emerging in the final decade of the 19th century, rejected the classical symmetry and gemstone hierarchy of earlier eras in favor of asymmetry, fluid linework, and naturalist inspiration. Rooted in the avant-garde ateliers of Paris—most notably René Lalique, Georges Fouquet, and Lucien Gaillard—this style viewed jewelry not as a frame for expensive stones, but as a holistic object where craftsmanship, material harmony, and symbolism outweighed carat weight or brilliance.

Rather than showcasing diamonds or faceted rubies, Art Nouveau artists turned to soft, translucent stones that lent themselves to atmospheric, dreamlike compositions. Moonstone, opal, chrysoprase, and adularescent labradorite were favored for their inner glow and color diffusion. Natural inclusions, clouding, and milky opalescence were not defects but enhancements, features that enhanced the movement’s fascination with fog, flora, and ephemeral light.

Lalique, in particular, pioneered the use of pâte de verre—a kiln-cast glass paste that he engraved or patinated to mimic misted surfaces or insect wings. He frequently combined this with materials like horn, enamel, ivory, baroque pearls, and uncut or cabochon-cut stones, crafting pieces that blurred the line between jewelry and sculpture.

Settings, too, reflected this ethos. Art Nouveau favored low-karat yellow gold, silver, or even bronze over platinum or high-carat gold, not for economy, but for their visual warmth and malleability. These metals could be chased, molded, or enamelled into sinuous forms—flowing vines, dragonfly wings, orchid petals, or mythological bodies—all executed in extreme detail.

In sum, Art Nouveau introduced an alternative gemstone hierarchy, one that elevated mood, movement, and material synthesis over clarity, symmetry, or price. It was a rejection of the jewel as an object of wealth, and a redefinition of it as a medium for narrative.

The close of World War I brought not just loss, but disillusionment. Art, once tasked with glorifying nature, religion, and nobility, stood hollow in the wake of mechanized slaughter. What comfort could floral curves offer when the trenches reeked of gas and steel? In this vacuum of meaning, new movements emerged, giving way to clean lines, repetition, and symmetry.

It drew heavily on Cubism (pioneered by Picasso and Braque), which arose from a desire to rebuild visual reality—to shatter the illusion of perspective and show multiple viewpoints simultaneously. It was analytical, cerebral, almost surgical in its deconstruction. The world, after all, had broken; Cubism mirrored the fragments.

Futurism, born in pre-WWI Italy, went further—reveling in violence, speed, and technology. It glorified the machine, the city, the factory, the engine—rejecting the past as dead weight. The old world had collapsed. Why pretend otherwise?

And the broader Machine Age ethos, which elevated the industrialized West: an aesthetic of progress. Function became beauty. Mass production became modernity’s badge of pride. Where Art Nouveau had curled into nature, Art Deco forged through modernity: abstraction, reproducibility, and power. Beauty was no longer bound to the natural world, it was engineered.

Jewelers absorbed these ideologies both in form and fabrication. Faceting machines, adapted from Swiss horology, introduced angle-adjustment plates, index gears, and precise quills (dops), tools developed in clockmaking, into the realm of lapidary. These rigs enabled cutters to sculpt gemstones with unprecedented control, generating mirror-like facets and mathematically reproducible geometries that mirrored the new aesthetic order.

Asscher Cut (patented in 1902): Square, step-cut with a high crown and dramatically beveled corners, evoking the concentric rigor of Cubist design.

Baguette Cut: Long and rectangular, often used in linear layouts, structural beams in miniature, echoing Futurist dynamism.

Emerald Cut: Wide tables, clipped corners, and planar elegance, designed to exalt internal clarity over optical fireworks.

Triangle, kite, and bullet cuts: Angular innovations that facilitated compositions defined by repetition, linearity, and the rhythm of machines.

These hard-edged geometries found their ideal counterpart in platinum—a metal stronger than gold yet pliable enough to craft impossibly delicate settings. Its strength allowed jewelers to construct lace-like scaffolding with structural integrity, permitting bolder, more architectural forms. Designers such as Jean Fouquet and Raymond Templier pioneered this abstraction in high art, while houses like Cartier, Boucheron, and Van Cleef & Arpels translated it into luxury for a global clientele.

They showcased calibré settings, where diamonds, onyx, rubies, sapphires, and carved emeralds were custom-cut to fit flush like mosaic tiles.

In 1919, Belgian-born diamond cutter and engineer Marcel Tolkowsky published Diamond Design, a mathematical treatise that yet again reshaped the gemstone industry. His work proposed a set of ideal proportions—based on light reflection, refraction, and dispersion—for maximizing a diamond’s brilliance and fire. This was the first scientifically grounded blueprint for a faceted cut, the round brilliant.

Tolkowsky’s design specified a 58-facet structure (including the culet) with precise angles for pavilion depth (43.1%) and crown height (16.2%), and a table facet comprising roughly 53% of the diameter. These proportions weren’t arbitrary, they were calculated to reflect light internally and return it through the crown with minimal leakage.

Initially, adoption was slow. Traditional cutters were hesitant to sacrifice carat weight for optical performance. But by the 1940s and especially into the 1950s, the round brilliant gained momentum, not solely for its sparkle, but for its compatibility with mass production and machine-based precision.

The late 20th century brought with it the introduction of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing). Cutters could now simulate facet patterns digitally, calculate theoretical light performance, and map inclusions using 3D modeling before ever touching the rough.

At the cutting bench, laser sawing and kerfing replaced steel blades and hand cleaving, enabling smoother, thinner cuts with reduced material loss—particularly vital for high-value rough.

In parallel, micro-setting techniques, aided by microscopes and pneumatic tools, allowed gem setters to mount dozens—or hundreds—of tiny accent stones with extreme precision. This led to the popularity of pavé, invisible, and tension settings.

But perhaps the most transformative development came not from cutting itself, but from the stones themselves. The advent of lab-grown diamonds, almost identical in structure and composition to mined stones, freed cutters from constraints of rarity or value loss.

Rough could be grown large, clean, and consistent, allowing for experimentation with aggressive cuts, optical illusions, and non-traditional geometries. With no historical claim or scarcity to protect, lab-grown gems offered designers an expanded material vocabulary and a new level of creative freedom.

From the earliest cabochons, polished by flame and sand, to the mathematical precision of CAD-generated fantasy cuts, the history of gemstone shaping is a chronicle of humanity’s evolving relationship with matter, light, and meaning.

Each era, from sacred Proto-Cuts to the philosophical restraint of Indian cleaving, Iberian medieval silence, Renaissance geometry, Victorian sentiment, industrial mechanization, Art Nouveau’s organic poetry, Art Deco’s machine-age rigor, and finally the stainless creativity of modern lab-grown and laser-engineered stones, reveals a distinct worldview.

Yet across centuries and continents, one truth remains, gemstones mirror the cultures that shape them. Here at North Way Studio, we honor this lineage. We reject the notion of a mere commodity and embrace stones as dynamic collaborators, each deserving of a cut that reflects its geometry, ancestry, and story.